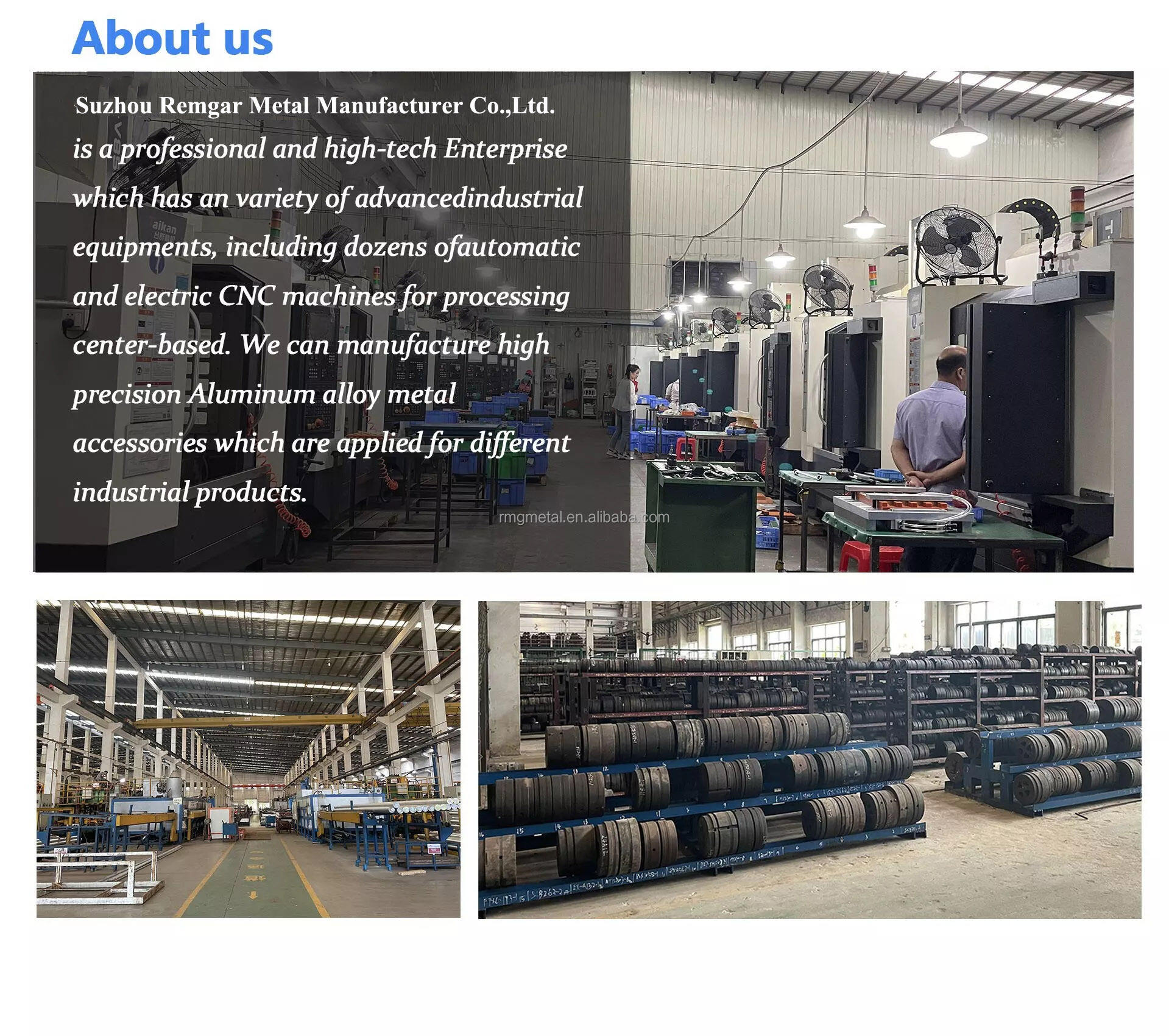

Introducing, the Remgar’s High Power CNC Extruded Enclosure Heatsink Profile Radiator Cooler, the perfect solution for keeping your car amplifier running cool and efficiently. This innovative product is specifically designed to dissipate heat generated by high power IGBT extrusion aluminum car amplifiers, ensuring optimal performance and longevity.

Crafted with precision using advanced CNC extrusion technology, this heatsink profile radiator cooler boasts a sleek and durable design that not only enhances the aesthetic appeal of your car amplifier but also improves its overall functionality. The extruded aluminum construction provides excellent thermal conductivity, efficiently transferring heat away from crucial components to prevent overheating and potential damage.

With a high power rating, this heatsink profile radiator cooler is capable of handling the demanding cooling requirements of modern car amplifiers, making it the ideal choice for audiophiles and car enthusiasts alike. Whether you're blasting your favorite tunes or pushing your system to its limits, rest assured that the Remgar’s High Power CNC Extruded Enclosure Heatsink Profile Radiator Cooler has got you covered.

Installation is a breeze thanks to the universal design and compatibility with a wide range of car amplifiers. Simply attach the heatsink profile radiator cooler to your amplifier using the included mounting hardware and watch as it efficiently absorbs and dissipates heat, keeping your system running smoothly even during extended listening sessions.

Say goodbye to overheating issues and hello to reliable performance with the Remgar’s High Power CNC Extruded Enclosure Heatsink Profile Radiator Cooler. Trust in the Remgar brand to deliver superior quality and innovative solutions for all your cooling needs. Don't compromise on the performance of your car amplifier – equip it with the best heatsink profile radiator cooler on the market and experience the difference for yourself. Elevate your audio experience with the Remgar’s High Power CNC Extruded Enclosure Heatsink Profile Radiator Cooler today

Product Name |

high power cnc extruded enclosure heatsink profile radiator cooler igbt extrusion aluminum car amplifier heat sink |

Material |

extrusion aluminum 6063-T5,6061-T6. - al, mg, si0.5, f22 |

Detailed Size |

As the below drawing, or as per custom design |

Max Aspect Ratio - Fin Height / Fin Gap |

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machine by most advanced technology |

Max Width |

500mm+/Ultra wide extruded heatsink can be made by our unique friction welding technology |

Standard Mold Qty |

30,000+ sets standard molds in stock for your option, saving your R&D cost |

Sample Service |

Samples with different sizes are available for prototypes test within 1 week |

Production Process |

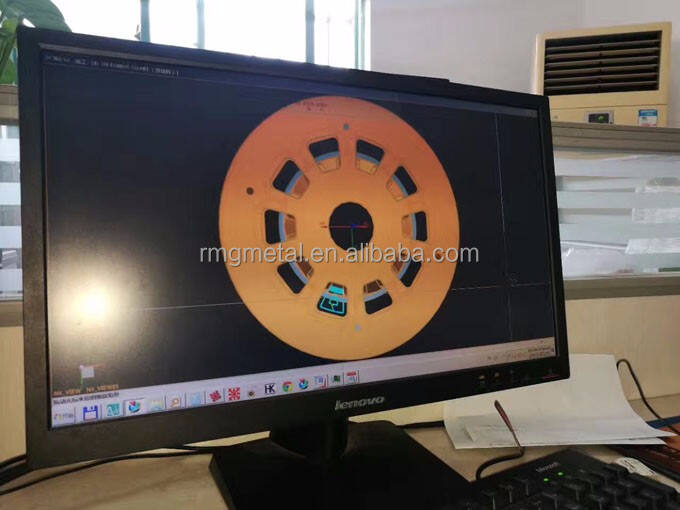

H13 Mould-Profiles Extruding---Cutting---CNC Machining(Milling, Turning, Drilling, Tapping)---Deburring--- Cleaning--- Inspecting--Packing |

Surface Treatment |

Degreasing, (Black) Anodizing, Sand Blasting, Painting, Chromating and Laser marking, powder coating |

Reference Standard |

GB/T 3190-2008, GB/T 14846-2008, ISO 2768 |

Experience |

More than 20 years professional manufacturing experience |

Application |

LED Lighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems, etc |

CUSTOM ALUMINUM EXTRUSION

1. More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology

2. Large size hat sink extrusion expert

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method