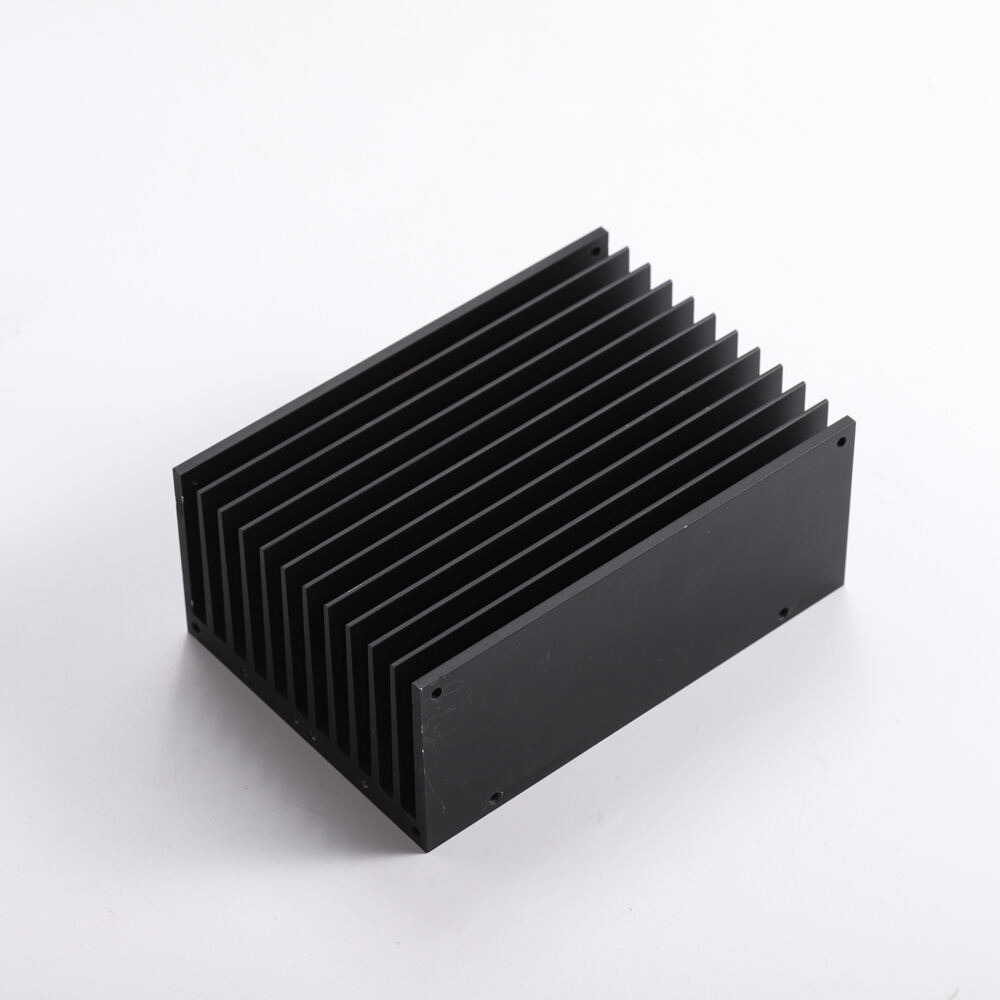

Why is 6063 aluminum profile selected as the heat sink for electronic extrusions?

Electronic devices have seamlessly integrated into our daily lives, and we truly can't do without their convenience. For many people, the first thing they do upon waking is grab their phone, turn on the stereo, and start a new day. But did you know? While we use electronics daily, few pay attention to their heat dissipation. Proper cooling is crucial—poor heat management can lead to explosions, component damage, and other serious incidents. Next, we'll explain why 6063 aluminum extrusions are the preferred choice for electronic heat sinks.

First, 6063 aluminum profile heat sinks exhibit excellent thermal conductivity.

Its excellent thermal conductivity effectively aids in dissipating heat from electronic devices. Among aluminum extrusion heat sink materials, each substance exhibits distinct thermal conductivity properties. Ranked from highest to lowest thermal conductivity, they are silver, copper, aluminum, and steel. However, using silver for heat sink would be prohibitively expensive, making copper the optimal choice. Although aluminum is significantly cheaper, its thermal conductivity is notably inferior to copper (approximately 50% of copper's value).

Currently, the most common materials for aluminum profile heat sinks are copper and aluminum alloy, each with distinct advantages and disadvantages. Copper offers superior thermal conductivity but is expensive, difficult to process, heavy, has low thermal mass, and is prone to oxidation. Pure aluminum is too soft for direct use; aluminum alloys are employed to provide sufficient hardness. Aluminum alloys offer advantages in lower cost and lighter weight, but their thermal conductivity is significantly inferior to copper. Some heat sinks combine the best of both materials by embedding a copper plate into the base of an aluminum alloy heat sink. This approach addresses cost concerns while ensuring effective heat dissipation.

Second, 6063 aluminum profile heat sink feature low density, making them easier to process into other components with simple installation and convenient maintenance. Due to the low density of aluminum alloy and its ability to be machined into various shapes and specifications, these heat sinks boast large, uniform cross-sections. Product assembly and surface treatment can be completed in one step, allowing direct installation at the construction site. This significantly reduces installation costs and facilitates maintenance.

Third, 6063 aluminum profile heat sinks offer high plasticity. They support diverse surface treatments with numerous decorative options, feature seamless welds, and deliver strong aesthetic appeal. Their durable, attractive design meets personalized demands. Suzhou Remgar Metal further enhances their appearance through processes like sandblasting, brushing, polishing, surface anodizing, and hard anodizing.