With the continuous optimisation of global energy structures and advancements in renewable energy technologies, power electronics play an increasingly prominent role within new energy systems. From photovoltaic inverters to wind power generati...

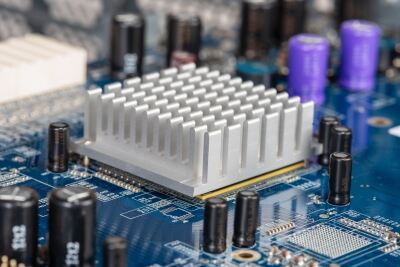

With the continuous optimisation of global energy structures and advancements in renewable energy technologies, power electronics play an increasingly prominent role within new energy systems. From photovoltaic inverters to wind power generation systems, and extending to energy storage systems and new energy vehicles, power electronic devices are virtually ubiquitous. However, the demands for high power density, high efficiency, and extended service life result in these devices generating substantial amounts of heat during operation. If this heat is not effectively managed, it not only reduces device efficiency but also severely compromises system reliability and service life. Consequently, as the core component of thermal management in power electronic systems, the design and application of heat sinks hold significant importance for the development of the new energy industry.

Power electronic devices such as IGBTs, MOSFETs, and power diodes generate substantial heat under high-frequency, high-power operating conditions. Temperature increases lead to heightened switching losses, elevated conduction impedance, accelerated semiconductor material ageing, and may even trigger thermal runaway. Consequently, heat sinks in power electronic systems serve not merely as passive cooling tools but as critical components ensuring system stability, extended lifespan, and enhanced efficiency. Particularly in new energy applications, where power devices often operate continuously under fluctuating ambient temperatures, heat sink performance directly impacts reliable system operation.

Photovoltaic inverters form the core of solar PV systems, converting direct current into alternating current. Power devices within inverters generate heat during high-frequency switching operations. Inadequate thermal management may lead to reduced inverter efficiency or even shutdown. Common heat sink configurations include extruded aluminium heat sinks and liquid cooling plates. Extruded aluminium heat sinks enhance heat dissipation through optimised fin structures, enabling natural convection or forced air cooling. Liquid-cooled plates, conversely, utilise circulating fluids to remove heat, making them suitable for high-power-density or enclosed-environment PV inverters.

Charging stations generate substantial heat during efficient energy transfer, with heat sink performance directly determining reliability, safety, and operational lifespan. Core power modules (such as IGBTs or SiC MOSFETs) incur significant power losses when converting grid AC to battery-required DC, releasing this energy as heat. Failure to dissipate this heat promptly causes core components to overheat, leading to efficiency degradation, performance decline, or even permanent damage. An efficient thermal management system is fundamental to ensuring charging stations operate stably under high-temperature, high-load conditions and sustain their rated power output (e.g., 120kW, 360kW, or higher), directly impacting charging safety and user experience.

Currently, charging station thermal management primarily employs two technical approaches: air cooling and liquid cooling:

1. Forced Air Cooling Radiators: This is the common solution for early-generation and medium-to-low power charging stations. Its principle involves increasing the contact area between power components and air through cooling fins, then utilising fans for forced convective heat exchange. This approach features simple structure and lower cost, but its cooling efficiency is limited, fan noise is significant, and it is susceptible to environmental dust, making it difficult to meet the demands of higher power density development.

2. Liquid-cooled systems: For high-power rapid chargers (typically 150kW and above), liquid cooling has become the mainstream approach. This system employs liquid cooling plates that closely contact heat-generating components. After absorbing heat, the coolant transports it to a remote liquid-to-liquid or liquid-to-air heat exchanger (the main radiator) for dissipation. Liquid cooling significantly outperforms air cooling in efficiency, offers a more compact footprint, provides sealed protection for critical internal components, and substantially reduces noise. Currently, ultra-fast chargers even extend liquid cooling to the charging gun cable, ensuring safety and lightweight design under high currents.

The rapid advancement of power electronics and new energy systems imposes heightened performance demands on heat sinks. Through optimised design, judicious material selection, and intelligent control, heat sinks not only resolve thermal management challenges effectively but also enhance system efficiency, prolong component lifespan, and propel the sustainable development of new energy technologies. Looking ahead, with continuous progress in materials science and thermal management techniques, heat sinks will become indispensable core components within the new energy industry, providing robust technical support for achieving the green energy transition.