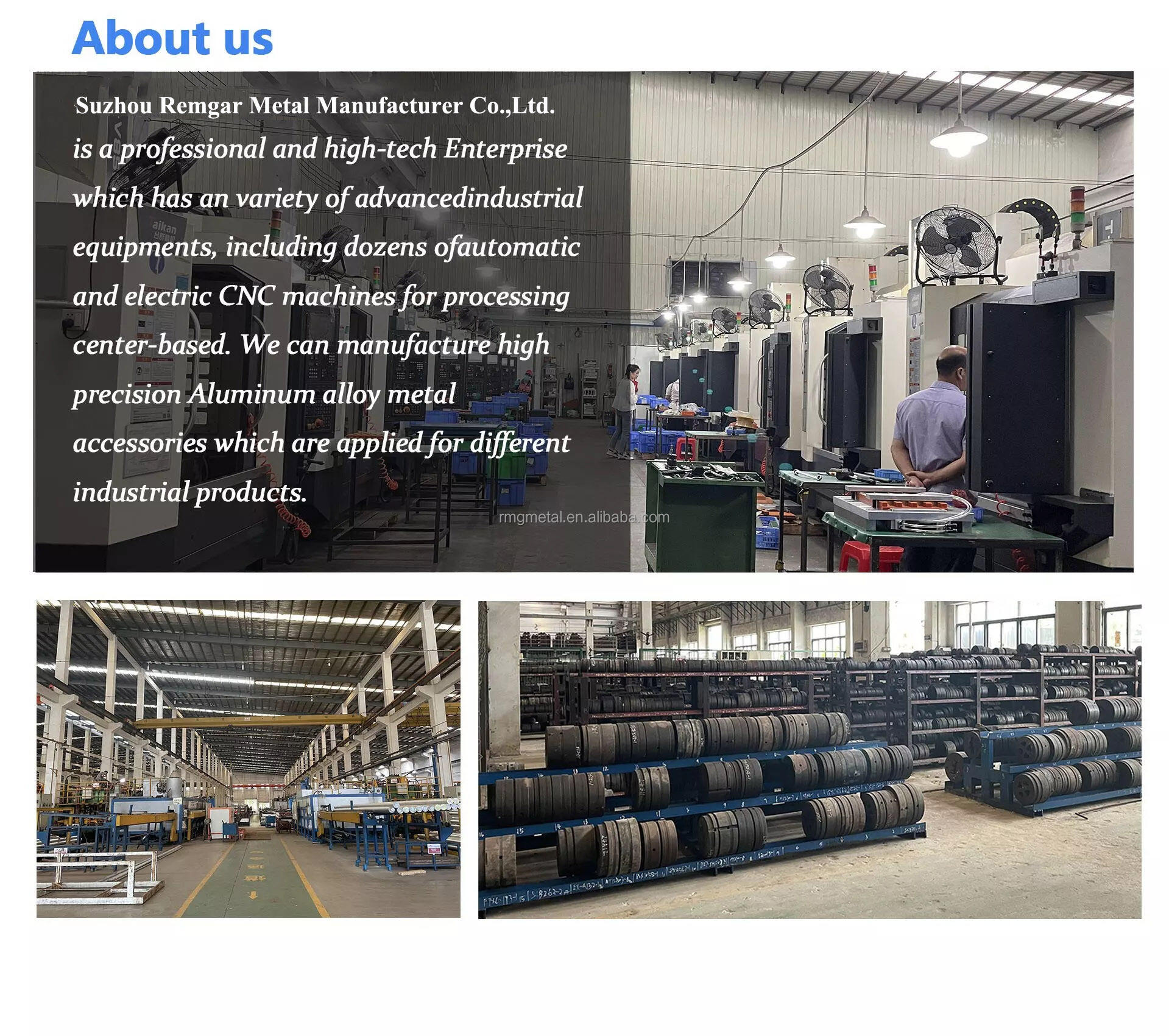

Introducing, the Remgar’s Custom Extrusion Aluminum Heatsink Profile Friction Stir Welding Cnc Machining Liquid Cooled Plate Heat Sink, the ultimate solution for all your cooling needs.

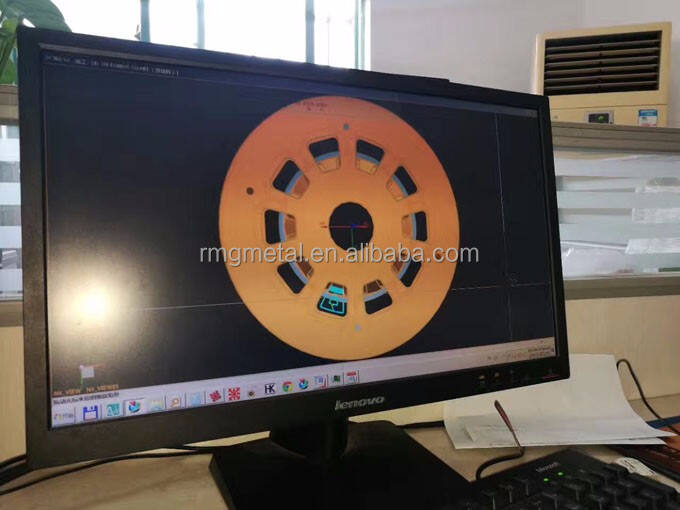

This innovative product is designed to deliver superior heat dissipation and thermal management for various electronic devices, ensuring optimal performance and longevity. The custom extrusion aluminum heatsink profile is precisely crafted using state-of-the-art CNC machining technology, guaranteeing a high level of precision and quality.

One of the key features of this heatsink is the friction stir welding technique used during its manufacturing process. This advanced welding method results in a seamless and durable bond, enhancing the heatsink's structural integrity and thermal conductivity. As a result, the Remgar heatsink offers excellent heat transfer efficiency, effectively drawing heat away from the electronics it is cooling.

In addition, the liquid-cooled plate heat sink design further enhances the cooling performance of the heatsink. The integrated liquid cooling system efficiently dissipates heat from the heatsink, preventing overheating and ensuring continuous and reliable operation of your electronic devices.

Whether you are using the Remgar heatsink for industrial applications, automotive electronics, or computer systems, you can rest assured that it will meet your cooling requirements with ease. Its versatile design allows for easy customization to fit your specific needs, making it a versatile and adaptable cooling solution for a wide range of applications.

With Remgar's commitment to quality and performance, you can trust that the Custom Extrusion Aluminum Heatsink Profile Friction Stir Welding Cnc Machining Liquid Cooled Plate Heat Sink will exceed your expectations. Invest in this cutting-edge cooling solution today and experience the difference it can make in maintaining the optimal operating temperature of your electronic devices

Product Name |

custom extrusion aluminum heatsink profile Friction Stir Welding cnc machining liquid cooled plate heat sink |

Material |

extrusion aluminum 6063-T5,6061-T6. - al, mg, si0.5, f22 |

Detailed Size |

As the below drawing, or as per custom design |

Max Aspect Ratio - Fin Height / Fin Gap |

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machine by most advanced technology |

Max Width |

500mm+/Ultra wide extruded heatsink can be made by our unique friction welding technology |

Standard Mold Qty |

30,000+ sets standard molds in stock for your option, saving your R&D cost |

Sample Service |

Samples with different sizes are available for prototypes test within 1 week |

Production Process |

H13 Mould-Profiles Extruding---Cutting---CNC Machining(Milling, Turning, Drilling, Tapping)---Deburring--- Cleaning--- Inspecting--Packing |

Surface Treatment |

Degreasing, (Black) Anodizing, Sand Blasting, Painting, Chromating and Laser marking, powder coating |

Reference Standard |

GB/T 3190-2008, GB/T 14846-2008, ISO 2768 |

Experience |

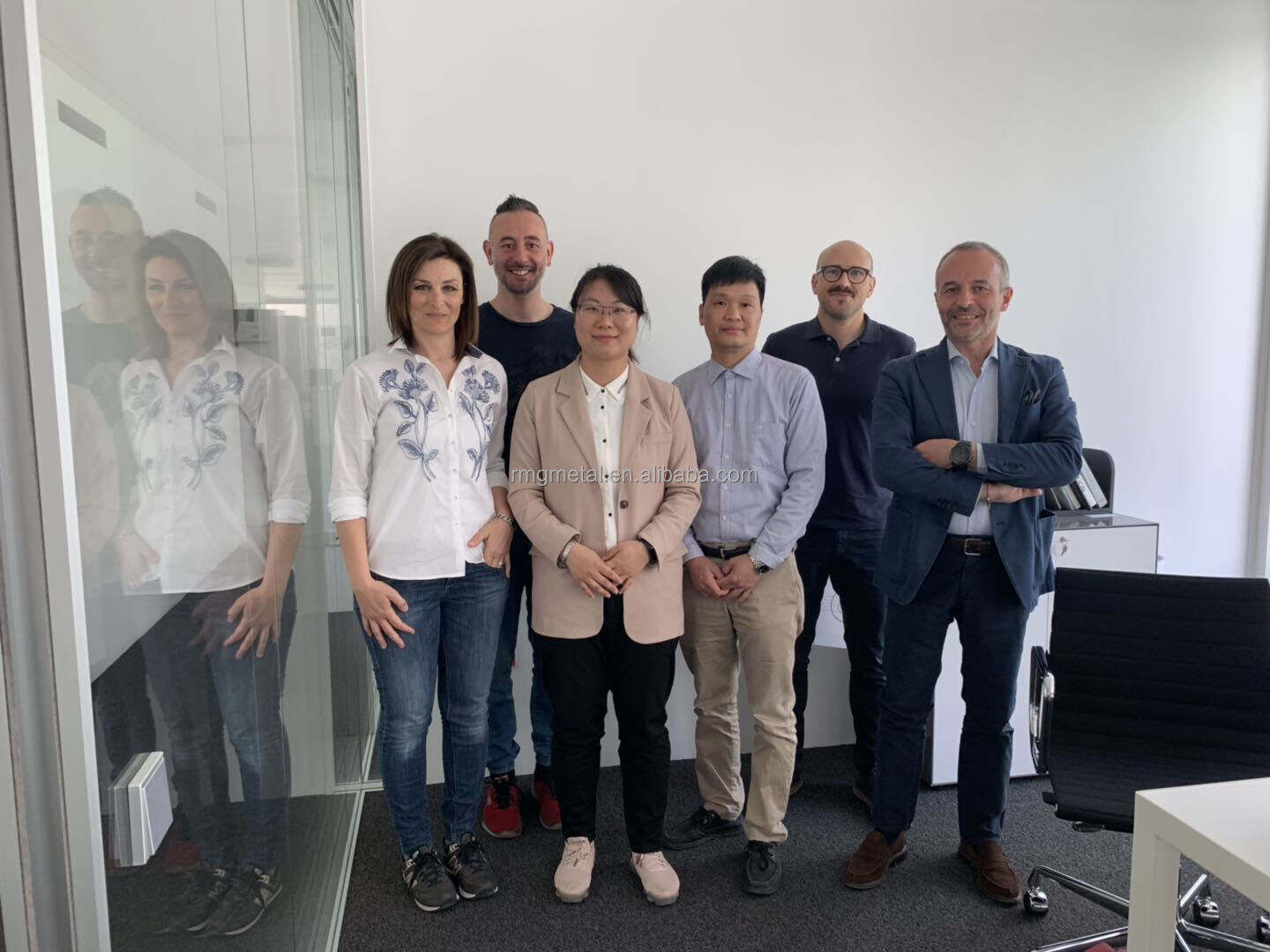

More than 20 years professional manufacturing experience |

Application |

LED Lighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems, etc |

CUSTOM ALUMINUM EXTRUSION

1. More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology

2. Large size hat sink extrusion expert

A: High heatsink surface;Good aerodynamics; Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method