In modern manufacturing and smart factories, industrial control and automation systems serve as the “brain” and “nervous system” of the entire production process. These systems encompass PLC controllers, industrial computers, ...

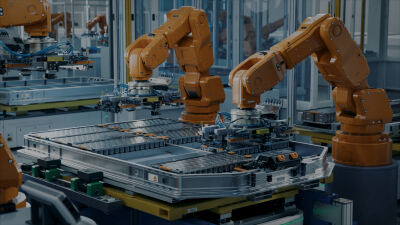

In modern manufacturing and smart factories, industrial control and automation systems serve as the “brain” and “nervous system” of the entire production process. These systems encompass PLC controllers, industrial computers, robotic drive modules, variable frequency drives, servo drives, industrial power supplies, sensors, and actuators, responsible for real-time monitoring, precise control, and data exchange along production lines. With the advancement of Industry 4.0 and smart manufacturing, equipment integration and power density have significantly increased, leading to growing thermal loads on electronic components and highlighting the critical importance of thermal management design.

Modern servo drives, variable frequency drives, and power modules are becoming increasingly compact, while their switching frequencies and output power continue to rise. This results in increased heat generation per unit volume, necessitating the use of more efficient heat sinks.Industrial settings often involve dust, oil mist, humidity, and even corrosive gases. Heat sinks must possess robust corrosion resistance and anti-clogging capabilities, while also being easy to maintain and clean.Continuous operation requirements. Many production lines operate year-round, 24/7. Heat dissipation systems must ensure long-term stability to prevent shutdowns caused by overheating, which could result in significant economic losses. Installation space constraints. Industrial cabinets offer limited internal space, necessitating compact radiator designs that maximise heat exchange efficiency within confined volumes while accommodating airflow organisation and electromagnetic compatibility.

During thermal design, engineers typically employ thermal simulation tools to model electronic components and heat sinks. This optimises fin geometry, spacing, and airflow paths to eliminate dead zones and minimise fan noise. Surface treatments predominantly employ anodising or thermal-conductive coatings to enhance corrosion resistance and radiative heat dissipation. For certain high-end equipment, intelligent temperature control systems are integrated to monitor component temperatures in real-time and adjust fan speeds, thereby achieving energy savings and extended operational lifespan.